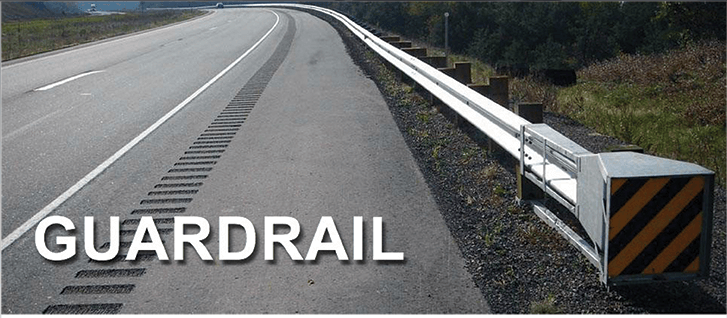

The consequences of not having guardrails on major roads are better left imagined; they provide much needed safety to pedestrians plying such roads.Guardrails are safety borders erected to prevent or minimize the fatal effects of an accident on highways.

This highway component is predesigned under specific guidelines to withstand varying impacts of vehicles, as specific details are taking into consideration. Resistance to these vehicular impact is determined by structure, and materials used during production. Durable materials like Steel Sheets, Aluminum, and Zinc are used during the production phase.

This article provides a broad view of the process of the installation of these longitudinal barriers.

Fabrication

These linear barriers are manufactured using specific international standards like the American Association of State Highway and Transportation Officials, AASHTO. They serve as guidelines to the fabrication of guardrail components like the actual parameters of the base beams, weight, thickness, length, and coating, etc.

Performance Test

Performance tests are carried out under controlled conditions of experts, where the guardrails are subjected to durability tests and destructive impact tests. The guardrails are subjected to crash testing from vehicles of different weights, to check for discrepancies during the fabrication stage.

The guardrails are moved to the site for installation once these requirements are met.

Installation

Proper installation ensures safer roads; hence it should be executed by contractors of high expertise. Specific details are taking into consideration at the site of installation. From the summary obtained, during manufacture, the lengths of the guardrails are clearly, to determine the start and finish points.

The guardrails are also mounted at a specific distance away from the edge of a reference roadway. This distance is known as the N-distance. This allowance creates sufficient sight distance for drivers on the highway and gives room for pedestrians as well.

The base beams are fitted in the ground to specification before fixing the longitudinal road railing using nuts and bolts. These rails are then intersected, considering the orientation of traffic flow in the carriageway.

Road lighting

In some countries, the guardrail houses the lighting components of the road. Cable Wires and other electrical requirements are passed through the rails into the parapet where they are connected. In other climes, the street lighting is directly constructed above the rail; the guardrails provide elevation.

Painting

It’s no gainsaying that guardrails add an element of class to highways. After all of the vital steel parts have been fabricated and welded together, the surface finishing and painting comes up. In some cases, defects are checked for in the setup and as the guardrail is needed to have a certain level of toughness. Many construction agents prefer the use of gloss paints on the guardrails for optimal shiny appearance. Also, the painting is needed to provide a certain level of visibility to the drivers using the road.

Final thoughts

The installation phase of this highway guardrail is as vital as the fabrication phase, as incompetence in execution renders the effort of the other stages futile and, consequently, yields ineffectiveness of these borders on the highway, as the primary objective of protection against safety hazard will be defeated.