Shot blasting is a technology that is used to polish, strengthen, and clean metal surfaces. That way they are ready for the application of coating or overlays. Some of the industries that rely heavily on shot blasting include aerospace, shipbuilding, construction, the automotive industry, and many others. It is considered that shot blasting is the most cost-effective technology for surface cleaning, removal of old layers of paint, and removal of rust.

As a result, once the targeted surface undergoes shot blasting it is fully ready for welding, powder coating, painting, or whatever process follows.

The process of shot blasting

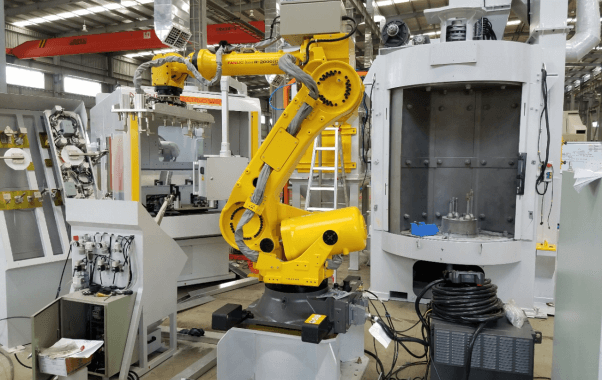

The process of shot blasting includes shooting tiny abrasive particles at a certain surface in a controlled environment. The final outcome mainly depends on factors such as the particle speed, density, size, and shape. The smaller the particles are, the smoother the surface will be, whereas the bigger they are, the surface will be somewhat rougher.

Shot blasting shares many similarities with sand blasting. However, sand blasting is illegal in the US because of the broken down sand containing silicon and can cause a form of lung cancer known as silicosis.

On the other hand, shot blasting doesn’t cause any disease and its abrasive particles can be recycled in full. That makes it one of the most cost-effective solutions on the market, in regards to surface cleaning.

The Importance of Surface Preparation

Surface preparation is not just the first thing you do to prepare a metal surface for any type of coating but is also the single most important step that determines the overall quality of the corrosion protection system.

If the surface protection is not done right, then the substrate material won’t adhere as it should.

Applications of Shot Blasting

The most common applications of shot blasting include:

- Oxidation and rust removal.

- Welding burns removal

- Burrs and flash removal

- Etching of various surfaces

- Coating removal

- Surface preparation

- Blending surface marks and scratches

Top Benefits of Shot Blasting

The list of benefits of shot blasting is a long one which holds significance across multiple industries. Here is just a fraction of the many benefits of shot blasting.

- Shot blasting can create the strongest possible bond between a metal surface and its coating. It is fair to say that no other technology can be that effective in that regard.

- Shot blasting can make a surface as smooth as silk or very rough. The level of smoothness or roughness can be adjusted as per the project’s requirements.

- Each particle can be recycled, reused, and there are zero chemicals included in the process. From that perspective, it is one of the most environmentally friendly surface preparation technology.

- Shot blasting is known to increase both the longevity and durability of the treated surface.

In Conclusion

Shot blasting is the most economical technology for surface preparations. It is an industry that remains strong despite any crisis. The demand for shot blasting machine China is ongoing even in time of the pandemic.

The reason why there is so much interest, despite everything this year, is because there are numerous industries that rely on it, from construction to automotive, and dozens other in-between. It will take more than a pandemic to halt this low-flying, but essential industry, to stop.