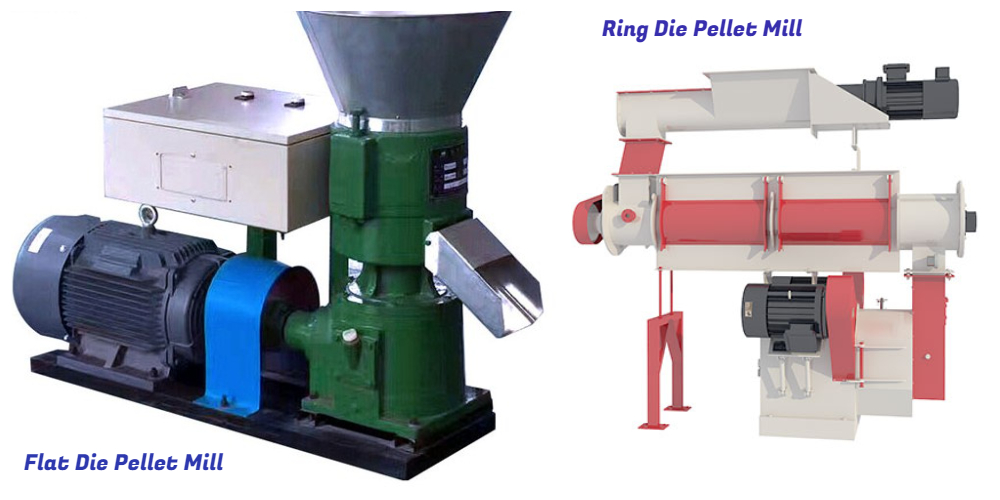

When you step into the market to purchase the pellet mill, you’ll get two options to choose from;

- Flat die pellet mill

- Ring dye pellet mill

These options are available in all the pellet mills, from china pellet machine to USA pellet mills. Both of these types differ in their mechanical working mechanism.

To choose a suitable pellet mill, the buyer must know what both of these types exactly are and how both are different from each other.

In this article, you’ll get complete detail about flat and ring dye pellet mills, so you’ll be able to pick the right one according to your applications.

If you are interested to know, read till the end!

What is a Flat Pellet Mill?

Flat die mills use flat dies with holes. The raw materials move downward and pass through these holes to attain their shape. The heavy roller over the die compresses and pushes the raw material over the die.

The flat pellet mills are of two types;

- Rotatory Die Mills: In these mills, the die rotates, and the roller keeps stationary

- Rotatory Roller Mills: In these mills, the roller rotates, and the die keeps stationary

After the pellet pass through the holes, the cutter cuts the pellets down into a specific size.

What is Ring Die Pellet Mills?

In the ring die mills, the die is in a ring shape with the rollers inside the ring. In these mills, both the die and roller rotate and pass the compressed raw material through holes. Material enters from the side of the die and distributes equally in the rotatory die.

Difference Between Flat and Ring Die Pellet Mills

• Design

The flat die mills have small, lightweight, and compact designs. These mills have a simple working mechanism and are the best option for small-scale applications.

Ring die mills have a much more complex mechanism than flat dies. These mills come up with customized and durable designs and are highly recommended for commercial use.

• Efficiency

The flat die mills are less energy efficient than the ring mills because these mills produce less wear and tear.

• Working Capacity

The working capacity of flat die pellet mills is up to 1000 kg per hour. In contrast, the ring pellet mills have a working capacity of up to 2 tons per hour.

• The Feeding Style

The raw material feeding style in flat die pellet mills is vertical. While in ring mills, the material is forced into the die from one side and distributed between the diameters of the ring.

• Die and Roller Rotation

In flat die mills, only one thing rotates at a time; die or roller, while in ring mills, both die and roller rotate for pellet formation.

• Price

Due to less efficiency, simple operation, and small design, the flat die pellet mills come up in a low price range as compared with ring die. Ring die mills have more features and working efficiency than flat die, but higher efficiency is required only on an industrial level.

Conclusion

From the structural design to working performance, flat and ring die pellet mills are completely opposite. If you are buying the pellet mill for small-scale use, choose the flat die over the ring dies pellet mill because of its easy mechanism.